Can I Buy An S5/S3 Maintenance Kit?

One of the most common questions I receive is: where can I find the Ultimaker S5/S3 maintenance kit?

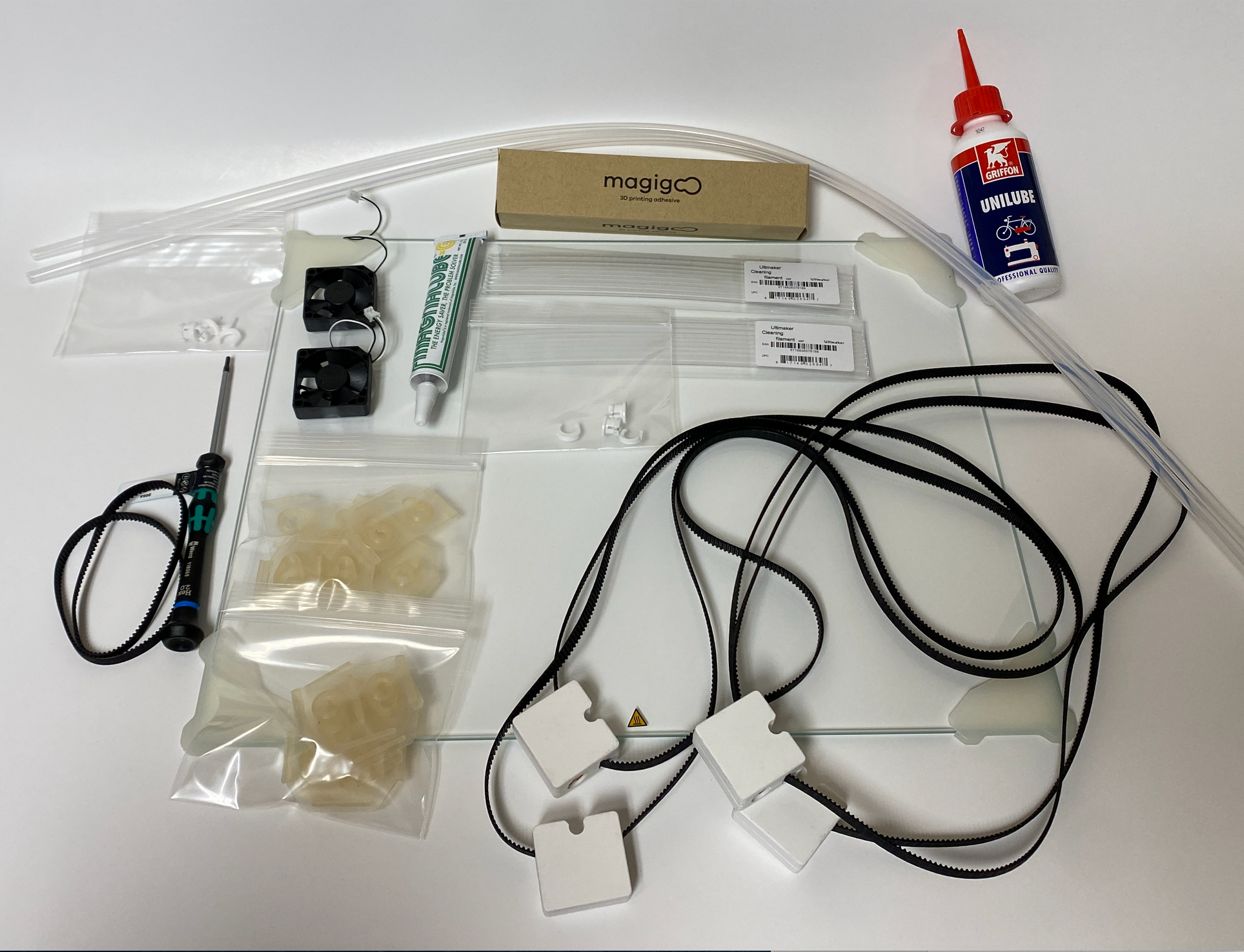

Ultimaker has not released an official S-Line maintenance kit. However, based on our extensive experience building and supporting these printers since their launch, we have put together a package of what we think are the most useful maintenance items to have, and they are now available in our store.

Because the parts are all available separately, you can also use this guide to put together your own kit that will best suit your needs. For example, if you're running multiple S-Line printers in high temperature materials, you'll want to make sure you have plenty of nozzle seals on hand. However, for those same printers, you probably still only need a single tube of Magnalube, which should last you for quite some time.

Here's the essentials I would put in my S5/S3 Maintenance Kit:

- Bowden Tube, Collets, Clips

- Bowden Tube and Collets and Clips (S5)

- Bowden Tube with Collets and Clips (S3)

- Front Fan (S5/S3)

- Nozzle Seals (S5/S3)

- Belts

- Short Belts (S5/S3)

- Sliding Block Set (S5)

- Sliding Block Set (S3)

- Glass

- Glass Plate (S5)

- Glass Plate (S3)

- Cleaning Filament

- Sewing Machine Oil

- Magnalube G

- Magigoo

Why these items? Most of the items listed are your soft parts, which are going to take the most wear and tear from friction or heat. Many of the others are consumables that are important for maintaining your printer.

Bowden Tubes, Collets, and Clips

Over time, the feeder end of the bowden tube can lose its clean 45 degree interior chamfer and start to look like someone has been chewing on it.

If the end of your bowden tube looks like that, your filament isn't going to to load as smoothly, and may struggle when changing materials mid-print if you're using the Material Station.

Your bowden tube can also end up with wear and tear on the interior of the tube, particularly if you're printing with harder or more abrasive materials. My favorite way to check for interior damage is to cut off a clean length of filament with a good point on the end; it's important for this to be smooth filament without any marks from the knurled teeth on your feeder. You don't need much, just a bit more than the full length of the tube. With your bowden tube disconnected from the printer, run the filament through it by hand, checking for any rough spots where it doesn't move smoothly. If you find any, it's time to replace your tube.

On the outside of the tube, you also want to look for excessive wear on the tube at the point where the collet sits. If the tube moves up and down easily when you tug it (without removing your clamp clip), it's time to replace your bowden tube and collets.

Front Fan

Your front fan, or axial fan, should be running any time either of your Print Cores is heated at 50 C or higher. It's critical for preventing heat creep in the upper part of your Print Cores so that the filament can feed smoothly. You cannot control it in the firmware settings or Cura, as it runs automatically when the correct temperature is detected, so there's no way to accidentally turn it off in your settings.

If it's not running, it's past time for some maintenance. If you're running your printer 1500 hours a year (roughly 30 hours a week), you'll want to open the fan bracket and clean the fan with a pair of tweezers once every three months or so. If you're running your machine 24/7 you'll want to clean it more often. Here are a a couple of examples.

If there's too much filament wrapped around the fan for too long, the fan may burn itself out.

Trying to print with a fan that's not moving fast enough (or not moving at all), will cause the filament to swell in the upper part of your Print Core due to heat creep as seen below. If it swells this way, it can be extremely difficult to remove from your Print Core.

Keep an eye on your fan and keep it keep it clean, but I also recommend keeping a spare around just in case you need it. As small a part as this is, it's critical to keeping your machine running healthily.

Nozzle Seals

Your nozzle seals at the bottom of your printhead serve two purposes:

- Help keep filament out of your printhead

- Help keep the heat in, so your filament keeps extruding smoothly.

If printing 1500 hours a year/30 hours a week, you'll want to inspect your silicone nozzle seal every 3 months or so to make sure it's in good condition as it can take damage from heat and friction during printing.

More importantly, if you're printing more often–especially with higher temperature materials like PC, PP, or Nylon–be sure to inspect it once a month or so, and keep plenty on hand if you're seeing damage.

Short Belts and Sliding Blocks

Just like the belts on on a car, the belts on your printer take wear and tear over time and can wear out. We usually recommend replacing the belts at around 3000-4000 print hours.

If you're not sure about runtime, here are some other signs to look for:

- Noise: if your perimeter rods and printhead shafts are well oiled, but quite noisy, the belts may be due for replacement. You can reach out to technical support to troubleshoot and isolate the noise to determine if the issue may be your belts or your printhead bearings. The noise sounds a bit like going over train tracks.

- Belt dust: when the belts are really starting to wear out, you may see black dust from the belts accumulating on top of your X and Y motors, as well as on the panels above them. A lot of dust would be a good indication that it's time to replace your belts.

You may also see wear and tear on the plastic blocks themselves on the long belts. The printhead shafts should fit snuggly into the blocks and snap into place to be held securely. If the blocks start to wear over time and your printhead shafts no longer fit tightly in them, it's time to replace the sliding blocks. One thing you absolutely do not want to do is wait so long that the printhead shaft come out in the middle of printing.

Glass

In case of damage to your glass, or for ease of use when printing multiple prints back to back, we recommend having a spare on hand.

To help avoid damage to your glass, put a protective layer of glue or Magigoo down.

Consumables: Cleaning Filament, Magnalube, Machine Oil, & Magigoo

Preventative maintenance is key to avoiding bigger problems later. Above all else, keep your machine clean and well lubricated.

If you're using high temperature materials, you will want to keep Cleaning Filament on hand for cleaning your Print Core when changing between high temperature and low temperature materials. PLA works fairly well for cleaning PLA out of your nozzle, but if you've been printing with PC, PP, or another high temperature material, you're going to need a high temperature cleaning filament to use with the cleaning wizard on your machine.

If you're printing with the CC Red Print Core using abrasive materials, you need to do a preventative cleaning about once a month in order to prevent hardened fibers from building up in the heat-break where they can cause damage.

Keep the four perimeter rods on your XY gantry clean and lubricated with sewing machine oil is important to keep the printer from missing steps--if the printhead hits a dry spot and takes too long crossing to the right location, you'll find yourself with an unusable shifted print. Keep a bottle of sewing machine oil on hand, and apply a drop or two to each of the four perimeter rods, the two vertical Z-shafts, and the two printhead shafts every month or so.

If you see dust or debris building up at the ends of your perimeter rods or printhead shafts, wipe it clean so it doesn't get caught in the moving pieces.

Similarly, you'll want to keep an eye on your threaded Z-screw for the same reason. If bits of filament or other debris get caught in your Z-screw, you could find yourself with unexpected bulges in your print. Wipe it down as needed with a lint-free cloth with a little isopropyl alcohol on it and apply a small amount of green Magnalube G it.

Magigoo is a great adhesive to protect your glass and help you get the best adhesions out of your prints. While there is a full line of Magigoo products specially developed for particular materials–Nylon, PC, GFPP–you can always start with Magigoo Original and then go from there based on your particular print needs.

If you have any questions, please reach out to our team and we'll be happy to help. We want to keep your machine in the best operating condition possible.

Leave a comment

Comments will be approved before showing up.

Also in News

Bambu Lab H2S Combo, First Impressions

We're excited to have added the new H2S Combo from Bambu Lab to our showroom in Memphis. It's keeping our P1S Combo company while they both churn out prints for us. It's a quick and easy set up to get started.

New Location, Just Off I-40

After 11 years serving the Mid-South from our location in Bartlett, TN, fbrc8 is excited to announce we moved of a new space in Memphis, just off Whitten and I-40.

Bambu Lab Machines From fbrc8

fbrc8 is pleased to announce that we have recently partnered with Bambu Lab, to offer their printers, filaments, and spare parts. The Bambu Lab printers offer a plug-and-play printer experience at home at an affordable price.