Ultimaker Engineering Materials

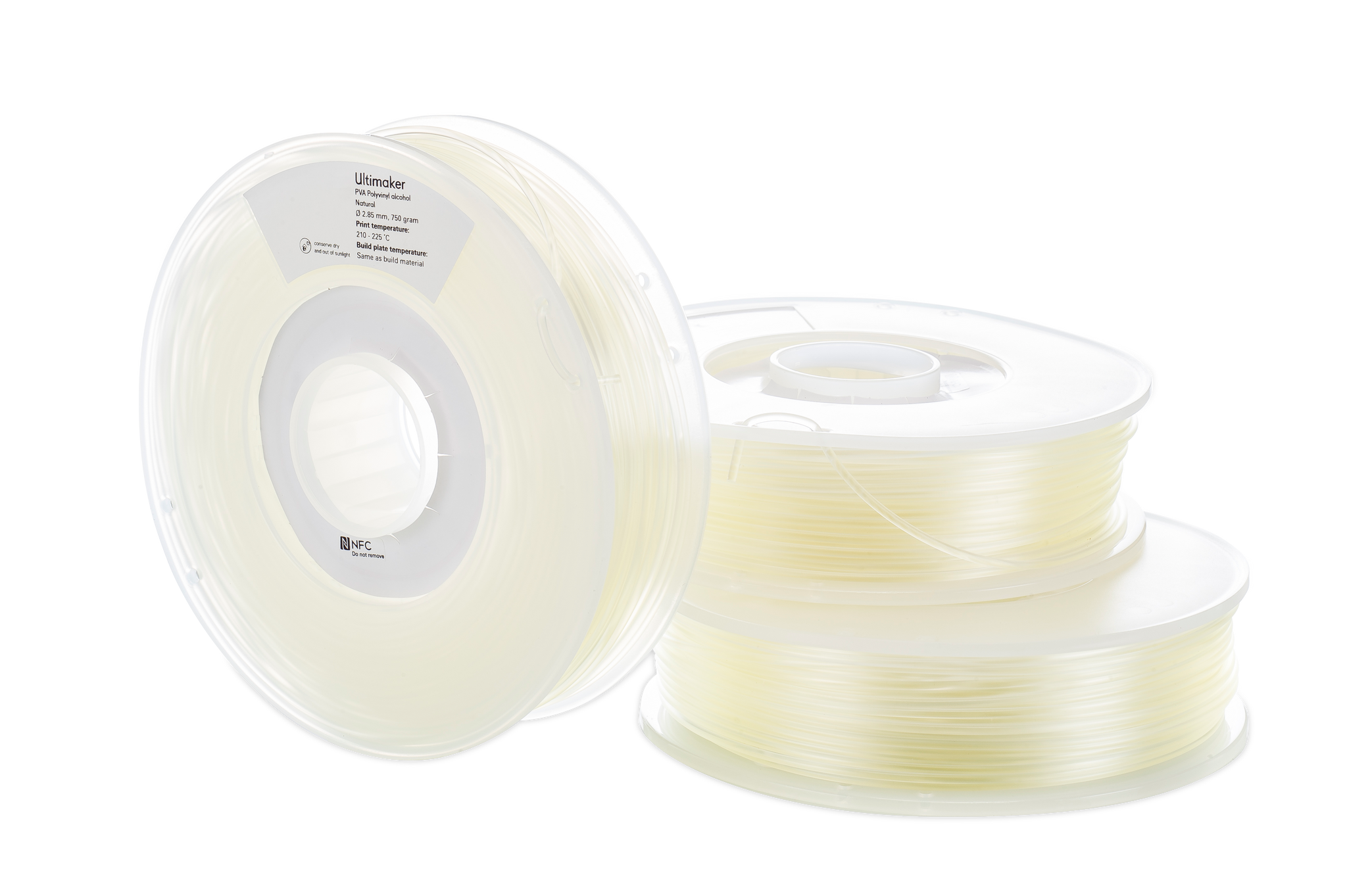

Ultimaker filaments are formulated to ensure the highest print quality and cover a wide range of uses. Enjoy a seamless 3D printing experience with optimized, preconfigured Cura profiles or easily customize them for your needs.

In particular, Ultimaker's Polypropylene, CPE+, Polycarbonate, Nylon and TPU materials are optimized to produce great results in demanding engineering and mechanical applications.